Project #2

American Automotive Company, Windsor, ON

2001/2002

Automotive Industry. Dual Multi-Pollutant CHR-FLUE™ Solutions Aluminum Chip Recycling and Aluminum Castings Application Ford Motor Company, Essex Aluminum Plant, Windsor, Ontario, 2001/02

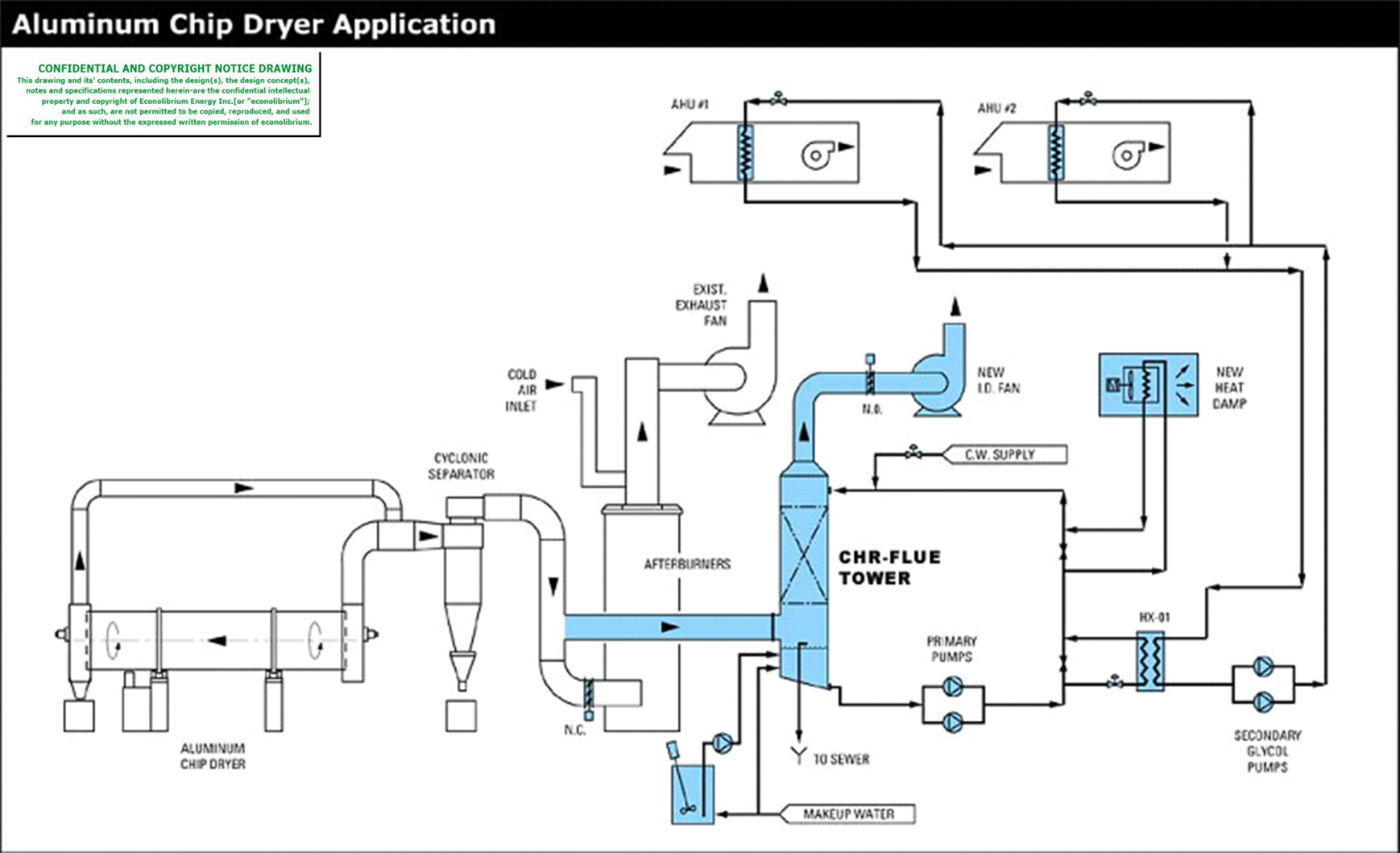

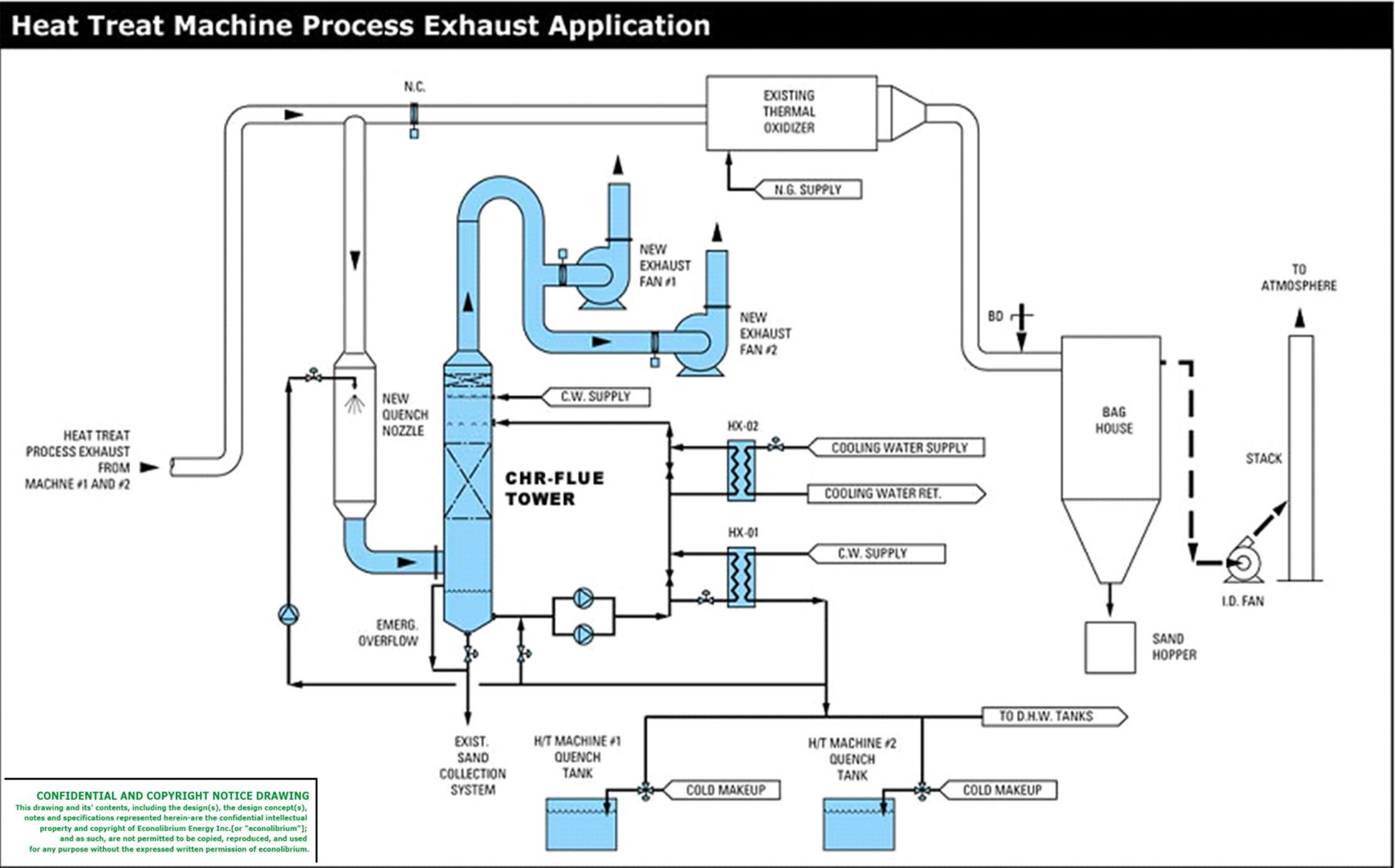

- Two distinct Hybrid “Multi-Pollutant” CHR-FLUE™ systems installed for two separate automotive parts manufacturing processes. Both systems were custom designed for combined APC (PM and VOC) and HR application to: 1. Recycled aluminum chip rotary dryer exhaust 2. Aluminum castings heat treat machine exhaust

- First system replaced existing afterburner using recovered energy to heat plant make up air.

- Both CHR-FLUE™ systems replaced existing APC technologies, consisting of NG-fired thermal oxidizers and bag house. Recovered energy is being utilized to heat both process make up water and plant make-up air heating units.

- Annual utility energy savings of $600,000/year (in year 2001), which today is valued at $1,200,000/year

- Financial payback was 3.5 years (in year 2001); however, would be < 2.5 Years payback based on today’s higher energy savings

- In addition to substantial energy savings, the automotive manufacturer reduced emissions of: Carbon dioxide (CO2) by 8,000 metric tons a year; Nitrogen Oxides (NOX) by 10 metric tons a year; Unburned hydrocarbons (THC) by more than five metric tons a year.