Project #1

Bruyère Continuing Care –

Saint Vincent Hospital,

Ottawa, ON

2016/2018

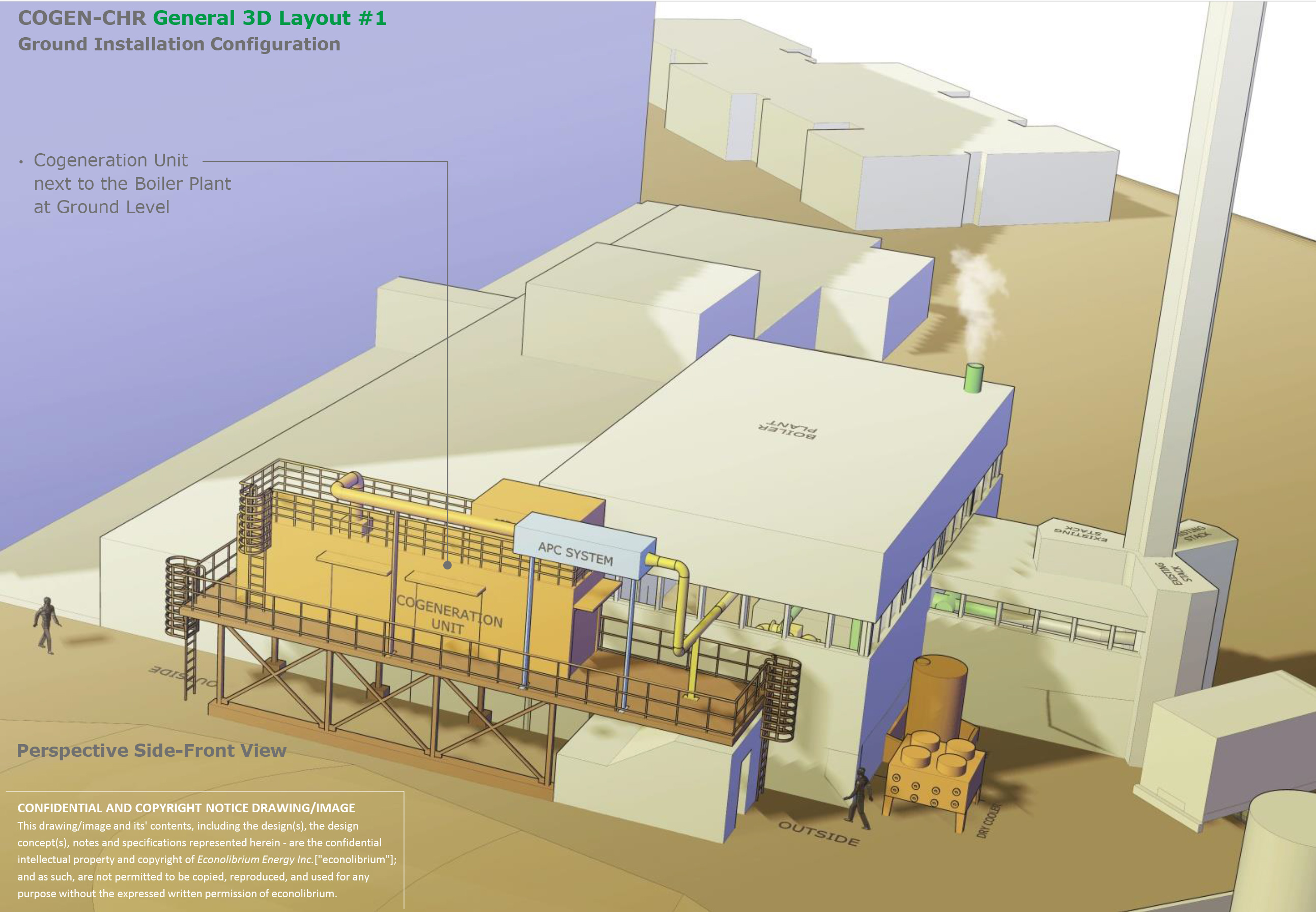

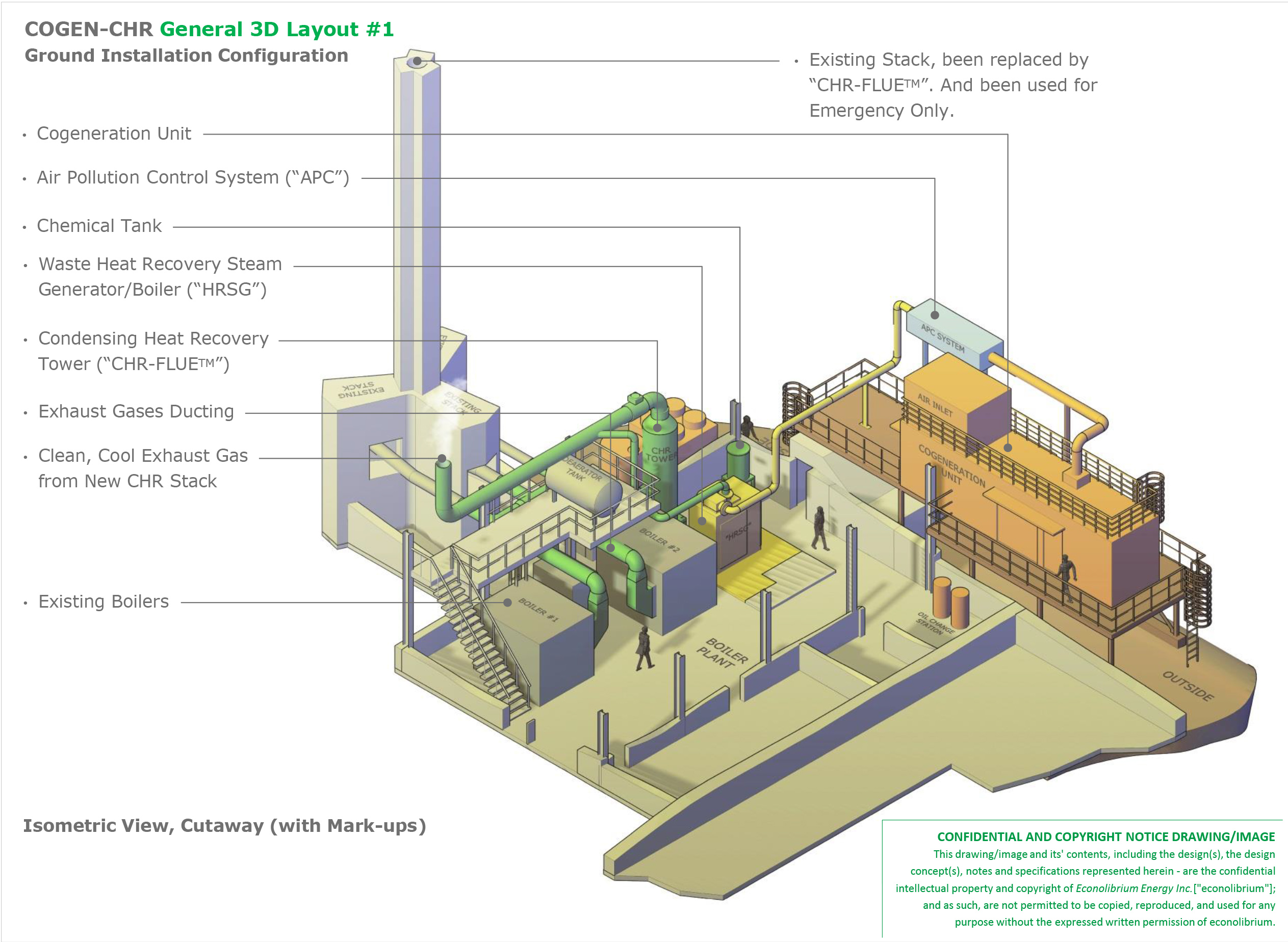

98% High Energy Efficient (“HEF”) Cogeneration + Boilers + CHR-FLUETM Condensing Heat Recovery (“CHR”) Solution at Bruyere Continuous Care (“BCC”) St. Vincent Hospital (“STVH”), Ottawa, Ontario (2016/18).

- Replaced Old (1994) CAT – 425 kW – COGEN with New GE – Jenbacher J-312 633kW – COGEN + replaced Old Boilers Flue-Gases (“FG”) mild steel Duct Work with New SST “0-leakage/Air-tight” Duct Work + Retrofitted & Expanded (1994) CHR System into New CHR-FLUETM to increase Heat Recovery from combined COGEN + Boilers FGs

- < 98% High Efficiency (“HEF”) Combined COGEN + Boilers + CHR-FLUETM Solutions

- 82% (or 5,250,000 kWH/Year) generated of Total Annual (6,400,000 kWH/Year) BCC-STVH Power consumed

- > 90% of Fall + Winter BCC-STVH Power Produced

- 70% reduction of Power Unit Cost to ($0.05 CAD/kWH, or $0.038 USD/kWH) – [Annual Average]

- $700,000 CAD/Year (or $525,000 USD/Year) saved on Utility Costs [Electricity + Natural Gas (“NG”)]

- $1,024,800 CAD IESO-PSUI Capital Grant secured by Econolibrium for partial funding of BCC-STVH project

- 5.0 Years Net Financial Payback

- $0.0376 CAD/kWH (or $0.028 USD/kWH) Unit Cost of Power achieved during Fall-Winter period

- 25% reduction of CO2 FG Greenhouse Gases (“GHG”) emissions, and 70% reduction of NOx (as Nitrogen Oxide)

Video Interview – Réjean Proulx, Manager of Heat and Power Plants